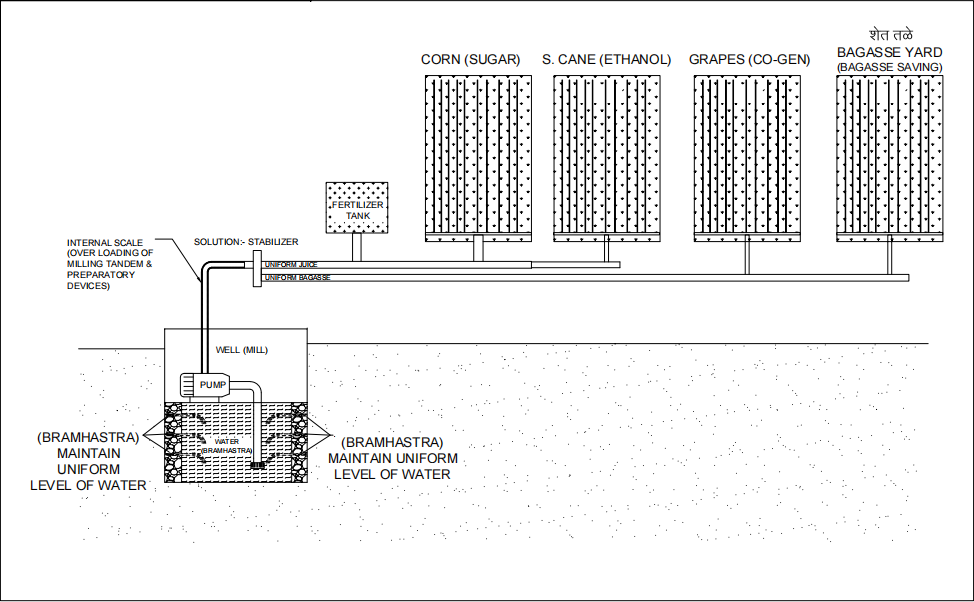

BRAHMASTRA

As per our design, machining, fabrication, manufacturing, assembly & supply of new concept,

heavy duty,

sturdy and result oriented special "Brahmastra” unit considering ultimate crushing capacity

of 6500 T. C. D.

In existing cane carrier width of 1525 m.m. with fibre % cane - 15

The unit should have futures for increasing cane feeding, cane carrier maximum capacity

utilization,

increasing bulk density, preparatory index and ultimately crushing rate by reducing further

load on

preparatory devices and milling Tandem.

The unit should run without gearbox at full RPM to achieve double result as compared to

other devices for

achieving targeted crushing rate of 6500 TCD.

It should help & participate along with our next unit “overall plant stabilizer” for uniform

cane preparation,

uniform bulk density of prepared cane & achieve our ultimate targeted goal of

- Uniform crushing.

- Smooth crushing.

- Consistent crushing.

- Constant crushing.

- Easy going crushing

- Uniform load on all Mills.

- To reduce wear & tear of mill parts & components

- To reduce Donnelly chute jamming.

- To reduce mill stoppages and breakdowns.

- To increase the overall profitability of sugar complex.

And Help factory for overall plant stabilization & synchronization of milling section, boiler

section, co-generation section, distillery section & sugar manufacturing process plant.

This should help factory for sure shot

- Increased crushing rate.

- Increased milling efficiency.

- Increased the boiler thermal efficiency.

- Increased average steam generation rate.

- Increased bagasse saving.

- Increased power export by reducing fluctuations.

- Increased co-generation plant thermal efficiency.

- Improved quality of sugar & RS, Ethanol due to uniform juice, uniform steam & uniform mixing

of chemical in to juice syrup steam & molasses.

How much is the profit of our new invented unit and consultancy if you increase 400 M.T. crushing per day

to any factory????